First published in the Harvard Business Review

First published in the Harvard Business Review

A renowned Indian heart surgeon is currently building a 2,000-bed, internationally accredited “health city” in the Cayman Islands, a short flight from the U.S. Its services will include tertiary care procedures, such as open-heart surgery, angioplasty, knee or hip replacement, and neurosurgery for about 40% of U.S. prices. Patients will have the option of recuperating for a week or two in the Caymans before returning to the U.S.

At a time when health care costs in the United States threaten to bankrupt the federal government, U.S. hospitals would do well to take a leaf or two from the book of Indian doctors and hospitals that are treating problems of the eye, heart, and kidney all the way to maternity care, orthopedics, and cancer for less than 5% to 10% of U.S. costs by using practices commonly associated with mass production and lean production.

The nine Indian hospitals we studied are not cheap because their care is shoddy; in fact, most of them are accredited by the U.S.-based Joint Commission International or its Indian equivalent, theNational Accreditation Board for Hospitals. Where available, data show that their medical outcomes are as good as or better than the average U.S. hospital.

The ultra-low-cost position of Indian hospitals may not seem surprising — after all, wages in India are significantly lower than in the U.S. However, the health care available in Indian hospitals is cheaper even when you adjust for wages: For example, even if Indian heart hospitals paid their doctors and staff U.S.-level salaries, their costs of open-heart surgery would still be one-fifth of those in the U.S.

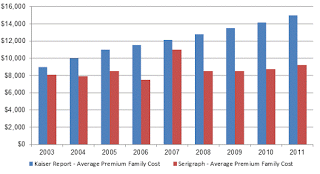

When it comes to innovations in health care delivery, these Indian hospitals have surpassed the efforts of other top institutions around the world, as we discussed in our recent HBR article. Today, the U.S. spends $8,000 per capita on health care; if it adopted the practices of the Indian hospitals, the same results might be achievable for a whole lot less, saving the country hundreds of billions of dollars.

A key to this is that, faced with the constraints of extreme poverty and a severe shortage of resources, these Indian hospitals have had to operate more nimbly and creatively to serve the vast number of poor people in need of medical care in the subcontinent. And because Indians on average bear 60% to 70% of health care costs out of pocket, they must deliver value. Consequently, value-based competition is not a pipe dream but a reality in India.

Three major practices have allowed these Indian hospitals to cut costs while still improving their quality of care.

A Hub-and-Spoke Design

In order to reach the masses of people in need of care, Indian hospitals create hubs in major metro areas and open smaller clinics in more rural areas which feed patients to the main hospital, similar to the way that regional air routes feed passengers into major airline hubs.

This tightly coordinated web cuts costs by concentrating the most expensive equipment and expertise in the hub, rather than duplicating it in every village. It also creates specialists at the hubs who, while performing high volumes of focused procedures, develop the skills that will improve quality. By contrast, hospitals in the U.S. are spread out and uncoordinated, duplicating care in many places without high enough volume in any of them to provide the critical mass to make the procedures affordable. Similarly, an MRI machine might be used four to five times a day in the U.S. but 15 to 20 times a day in the Indian hospitals. As one CEO told us, “We have to make the equipment sweat!”

U.S. hospitals have been developing similar structures, but there are still too many hubs and not enough spokes. Moreover, when hospitals consolidate, the motive often is to increase market power vis-à-vis insurance companies, rather than to lower costs by creating a hub-and-spoke structure.

Task Shifting

The Indian hospitals transfer responsibility for routine tasks to lower-skilled workers, leaving expert doctors to handle only the most complicated procedures. Again, necessity is the mother of invention; since India is dealing with a chronic shortage of highly skilled doctors, hospitals have had to maximize the duties they perform. By focusing only on the most technical part of an operation, doctors at these hospitals have become incredibly productive — for example, performing up to five or six surgeries per hour instead of the one to two surgeries common in the U.S.

This innovation has also reduced costs. After shifting tasks from doctors to nurse practitioners and nurses, several hospitals have even created a lower tier of paramedic workers with two years’ training after high school to perform the most routine medical jobs. In one hospital, these workers comprise more than half of the workforce. Compare that to the U.S. system, where the first cost-cutting move is often to lay off support staff, shifting more mundane tasks such as billing and transcription onto doctors overqualified for those duties — precisely the wrong kind of task shifting.

Good, Old-Fashioned Frugality

There is a lot of waste in U.S. hospitals. You walk into a hospital in the U.S., and it looks like a five-star resort; half of the building has no relation to medical outcomes, and doctors are blissfully unaware of costs. By contrast, Indian hospitals are fanatical about wisely shepherding resources — for example, sterilizing and safely reusing many surgical products that are routinely discarded in the states after a single use. They have also developed local devices such as stents or intraocular lenses that cost one-tenth the price of imported devices.

These hospitals have also been innovative in compensating doctors. Instead of the fee-for-service model, which creates an incentive to perform unnecessary procedures and tests, doctors at some Indian hospitals are paid fixed salaries, regardless of how many tests they order. Other hospitals employ team-based compensation, which generates peer pressure to avoid unnecessary tests and procedures.

Innovation has flourished in the U.S. in the development of new pills, clinical procedures, devices, and medical equipment, but in the field of health care delivery, it appears to have been frozen in time. In too much of the U.S., system, health care is viewed as a craft and each patient as unique. But by applying principles of mass production and lean production to health care delivery, Indian doctors and hospitals may have discovered the best way to cut costs while still delivering high quality in health care.